Sandblasting with One-&-Done Abrasives: 10 Reasons Why Crushed Glass and Coal Slag Should Be

I will assume everyone here has tested each of the 3 abrasives: Crushed Glass, Coal Slag and Garnet, and have a good idea which they prefer for various jobs. So instead of going into details of each, let’s just jump right into the list.

How to Follow OSHA Regulations With Dustless Blasting

BLACK BEAUTY Abrasive Blast Media Medium Abrasive 12/40 Mesh Size for use in Sandblast Cabinet - 10 LBS

Green Diamond Nickel Slag Abrasive

Blasting Media - Choosing the Right Abrasive (VIDEO)

Coal & Copper Slag Blasting Abrasive Supplier

Enviro-Grit Crushed Glass Sandblasting Media

Abrasive Blast Media

Abrasive Blast Media

Abrasive Blast Materials Manufacturers and Suppliers in the USA

Recycled Broken Crushed Glass Abrasive for Sandblasting Media - China Crushed Glass, Crushed Glass Chips

Sandblasting Machinery: What Is It? How Does It Work? Types

Maritime Guidance Documents Abrasive Blasting Hazards in

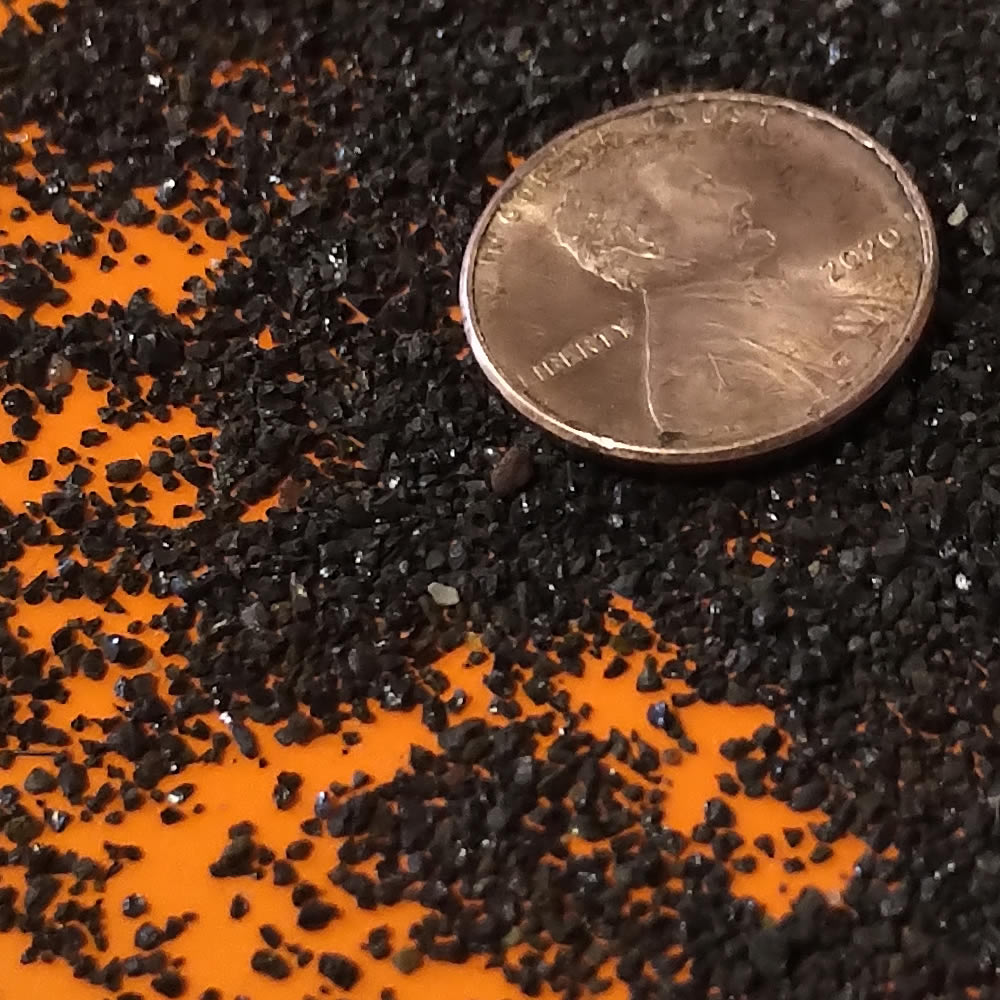

Coal Slag is generally used in a pressure or siphon blaster when paint, rust, and scale have to be removed from steel, such as car/truck frames, tanks, heavy machinery, farm equipment, etc. Coal slag is superior to silica because it contains 0.1% or less silica. Coal slag is moisture free and will not pack or absorb moisture. Coal slag is generally used once and is not recommended for use in a cabinet blaster.

ALC 25 lbs. Coal Slag Blasting Abrasive 40093