Eyelets - Custom Die Arbor Press - Use for our Custom Dies

Knife Making Supplies - Best prices, selection and service. Visit us Today!1

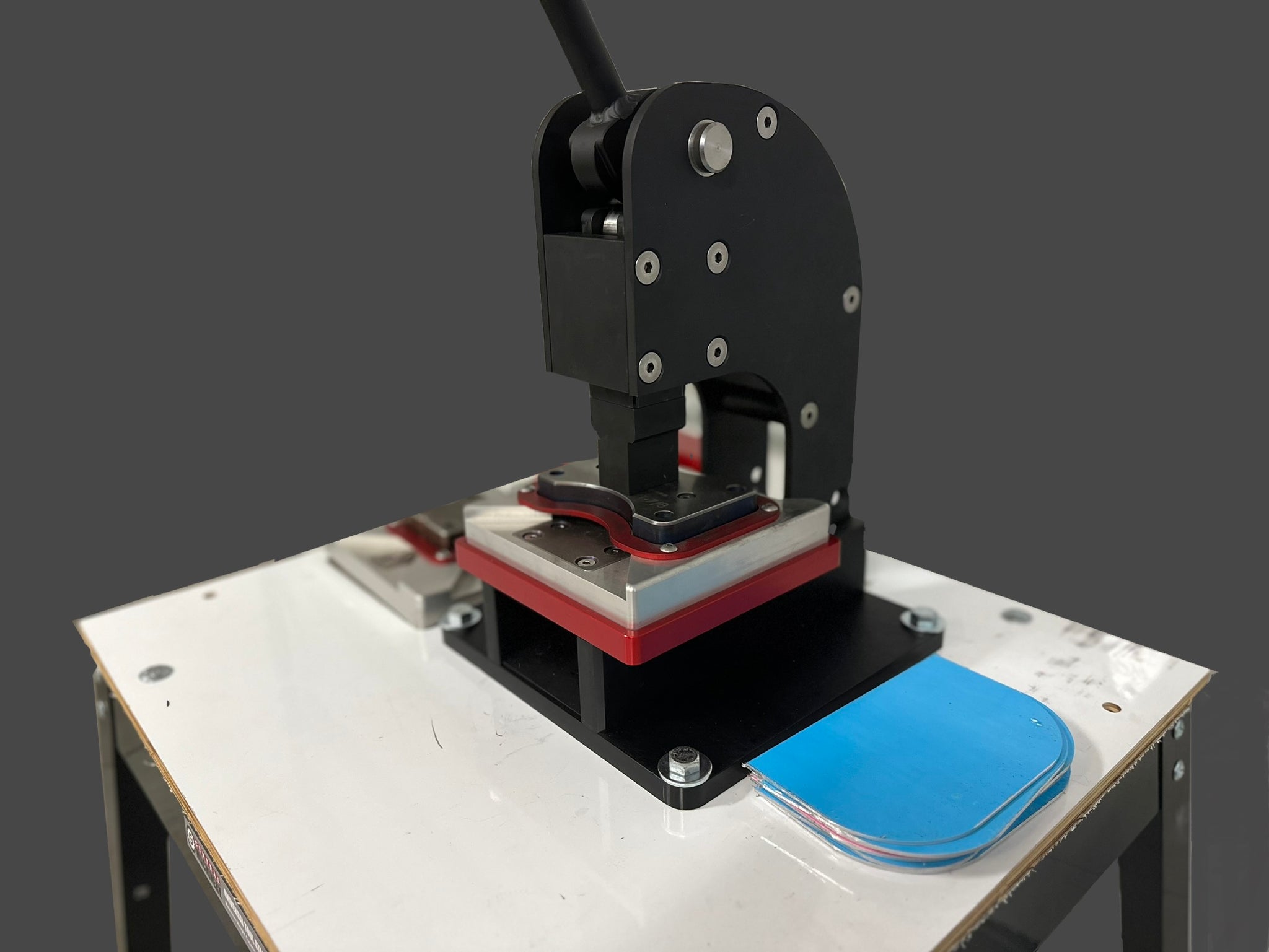

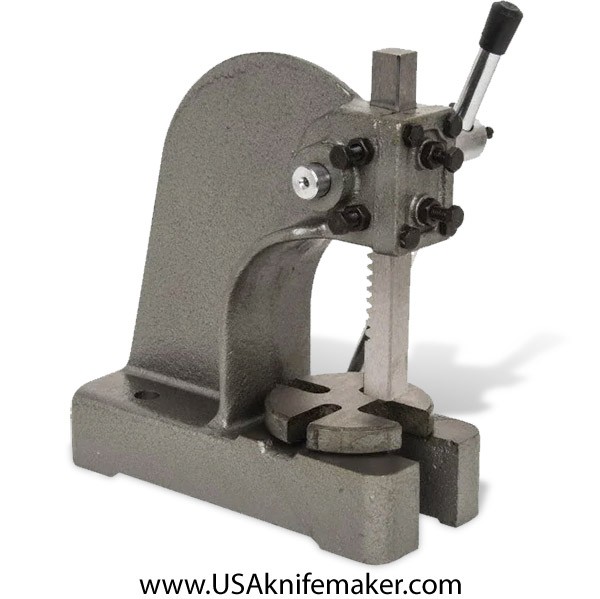

Custom Eyelet Die Arbor Press

1/2 Ton

Drilled for use with our custom eyelet die sets

NOTE NOTE NOTE: We drill the hole in the Ram and the Anvil to hold the dies but we do not use the index pin in the anvil to line it all up. The anvil (part that holds the bottom die) will float and move around on the press base. The hole in the bottom anvil holding the eyelet die will not line up with the hole in the ram holding the top die. See the video for more on this.

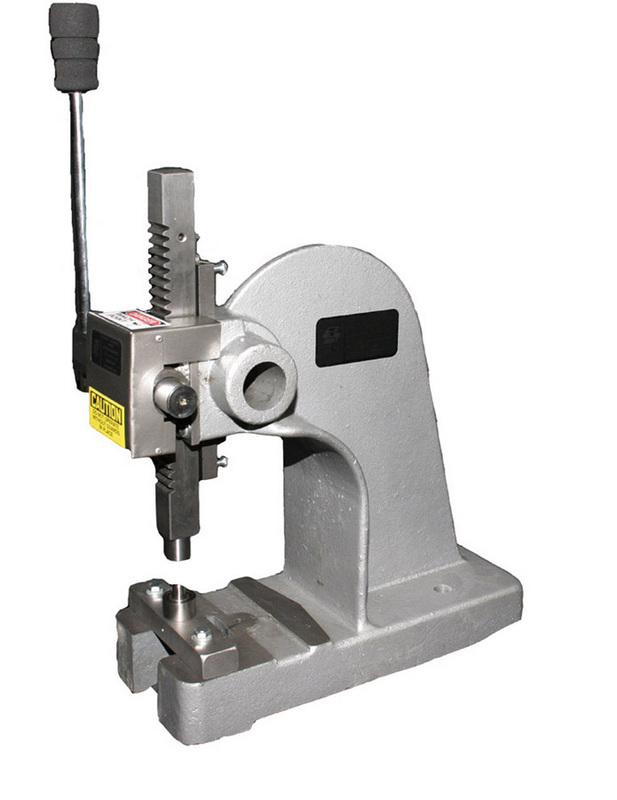

These 1/2 ton arbor presses are used with the eyelet custom dies we sell. We have done the drilling for you. These arbors will also hold the knifekits.com version eyelet dies. We need to note again, their eyelet dies and our eyelet dies do not come from the same source. They had theirs made, we had ours made. We think ours are better (of course) but we'll leave that up to you.

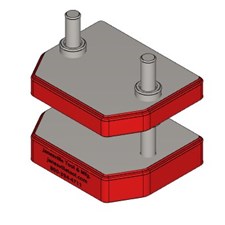

We drilled a 3/8diameter mounting hole in the ram bar and also drilled and tapped a set screw to hold the die in place. We also drilled a mounting hole in the bottom anvil.

In use, you put a die set into the press, pointy part of the die up. Drill your Kydex or Concealex holes, put the eyelet into the hole, sharp edge down, rounded over edge showing. Slide the pieces to be joined onto the point of the die and line it up with the top die (the bottom anvil is loose). Once you have it all lined up, press down with a short, sharp movement. It took longer to write the directions than it takes to use it.

Some notes on this arbor press: These are still covered in cosmoline grease and now a few metal shavings from drilling. You will have a little cleaning up to do. The bottom anvil (clover leaf looking part) is not indexed. It slides around loose. You will have to line up the bottom die with the top die in use with every press stroke. The reason for this is this arbor press is not that tight in tolerance and drilling the ram bar and anvil to precisely line up is a machinist job that would be too expensive. In use, this becomes a non-issue but it is worth noting.

NOTE: Dies are sold separately and are not NOT included.

The dies will be a tight fit in the Ram bar. There may be a burr to remove from the set screw. Tap the die in and out with a piece of wood and the burr will fall away with one or two uses.

The Art of Pressing: Exploring the Potential of Arbor Presses, by Tomellis

Eyelet / Grommet Dies for Hand Press - Chair & Chisel

4” foot only , Comes with set screw and Allen key, The one ton press is 1x1'' shaft , Made from 1/8 Steel - pressor feet ** most of the time we paint

1/8 thick 4 inch foot for one ton arbor press

Mold & Tooling Blank Die Sets Janesville Tool & Manufacturing, Inc. Janesville, Wisconsin 53546

Bench Press for Grommets or Eyelets, Table Top Presses - Siska Inc

Buy Press - Self Piercing Eyelet Dies

Eyelet Grommet Press Dies for Hand Press Dies for Setting Eyelets and Grommets Press Sold Separately 1

Grommet Machine W #2 Die & 600 Nickel Grommets Hand Press Tool Upgrad

Product Highlight: Rivet Bars & Punch Presses - Momentum Health Technologies

Custom Eyelet Die Arbor Press, 1/2 Ton, Drilled for use with our custom eyelet die sets, NOTE NOTE NOTE: We drill the hole in the Ram and the Anvil

Eyelets - Custom Die Arbor Press - Use for our Custom Dies

1/2 Ton Drilled for use with our custom eyelet die sets We drill the hole in the Ram and the Anvil to hold the dies but we do not use the index pin in

Custom Eyelet Die Arbor Press to use with our dies

Tutorial - How to Use Press Plates for Custom Die - Goldstartool.com - 800-868-4419

SHOP CATEGORIES