Fiber Lasers in Material Processing

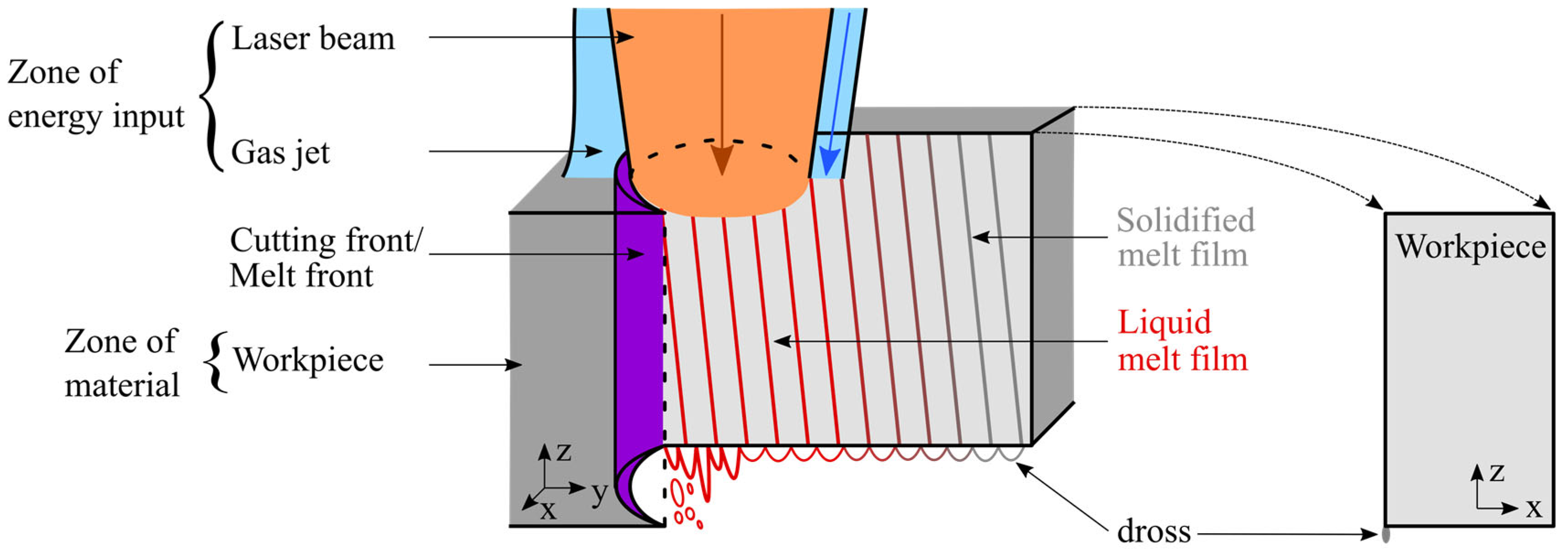

The economic aspects of laser usage in manufacturing that form important criteria in the choice of a suitable laser system for thick-section metal cutting include: high processing speeds, high processing depths, high cut edge quality, and high wall-pug efficiency of the laser system. Consequently, the performance of the high brightness ytterbium fiber laser system in thick-section metal cutting is evaluated based on the maximum achievable cutting speeds, maximum cutting depths possible, and cut edge quality attainable. The maximum processing speeds, maximum processing depths, and resulting cut edge quality are governed by a number of parameters related to the laser system, workpiece specification, and the cutting process. The effects of the processing parameters in the cutting of thick-section stainless steel and mild steel and medium-section aluminium have been reported; optimization of the processing parameters for enhancement of the cut edge quality has been discussed.

Laser Cutting: What Is It? How Does It Work? Methods

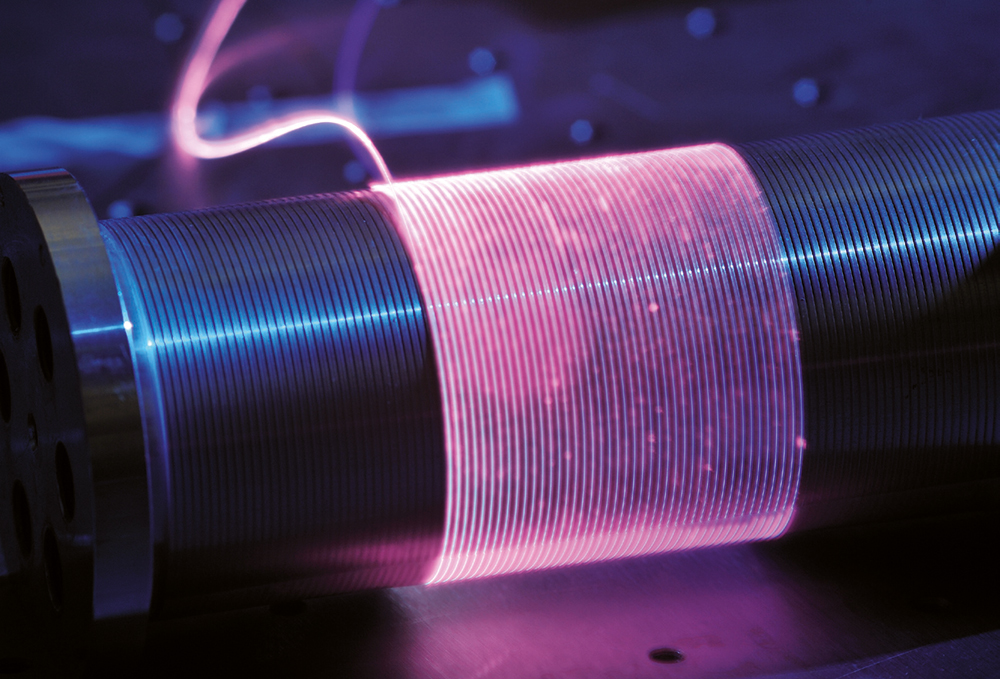

Fiber lasers: A versatile technology

Metals, Free Full-Text

Effect of ion beam-assisted deposition on the end pumping and outer coupler filters of a laser fiber

HP Brochure - IPG Photonics Corporation - PDF Catalogs, Technical Documentation

Fiber Laser: 7 Advantages and Differences

Fiber Lasers in Material Processing

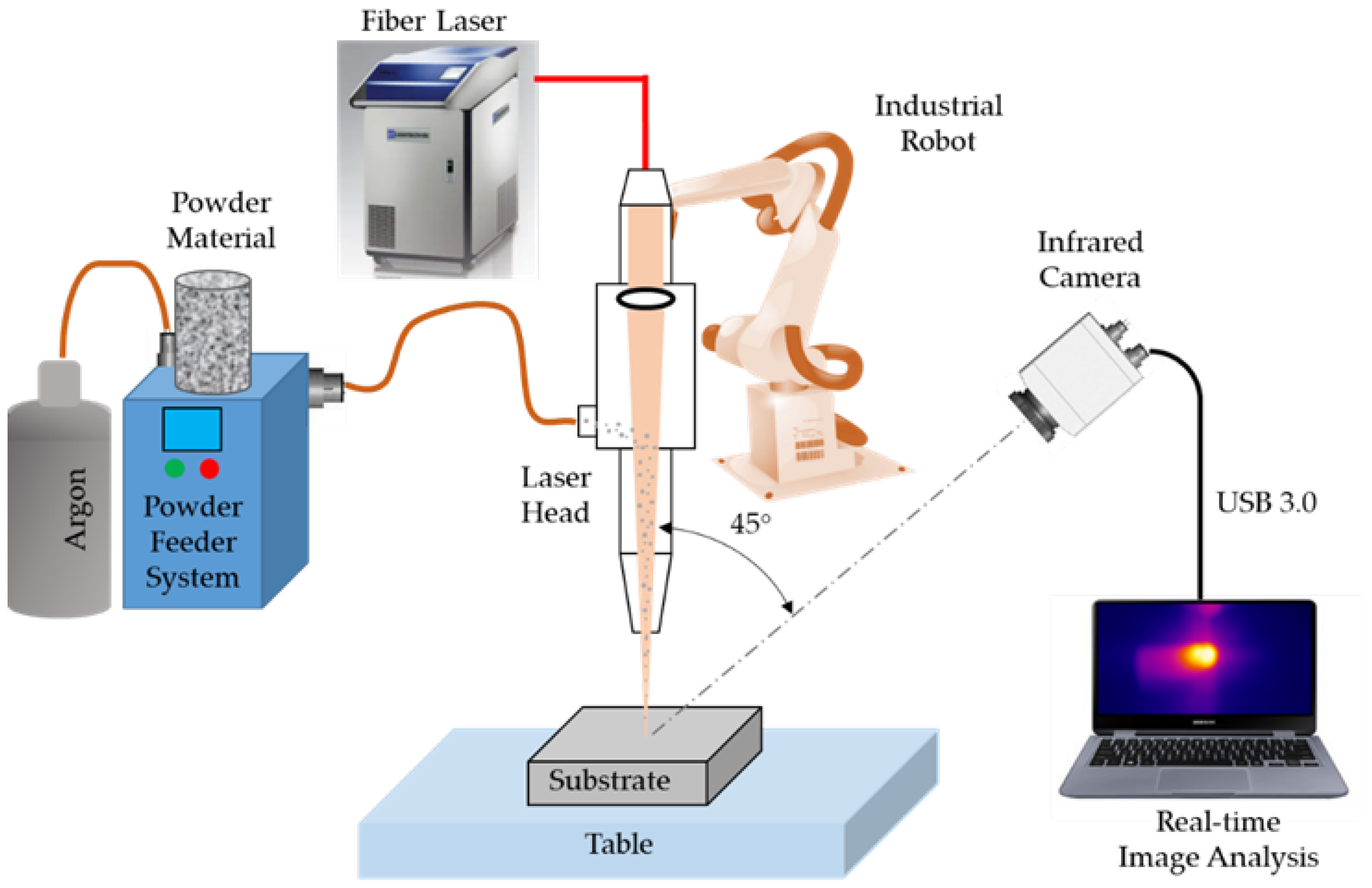

Metals, Free Full-Text

Sensors, Free Full-Text

What high-powered fiber lasers mean for a fabricating shop

Industrial Applications of Fiber Lasers