In-cycle spline milling saves production costs

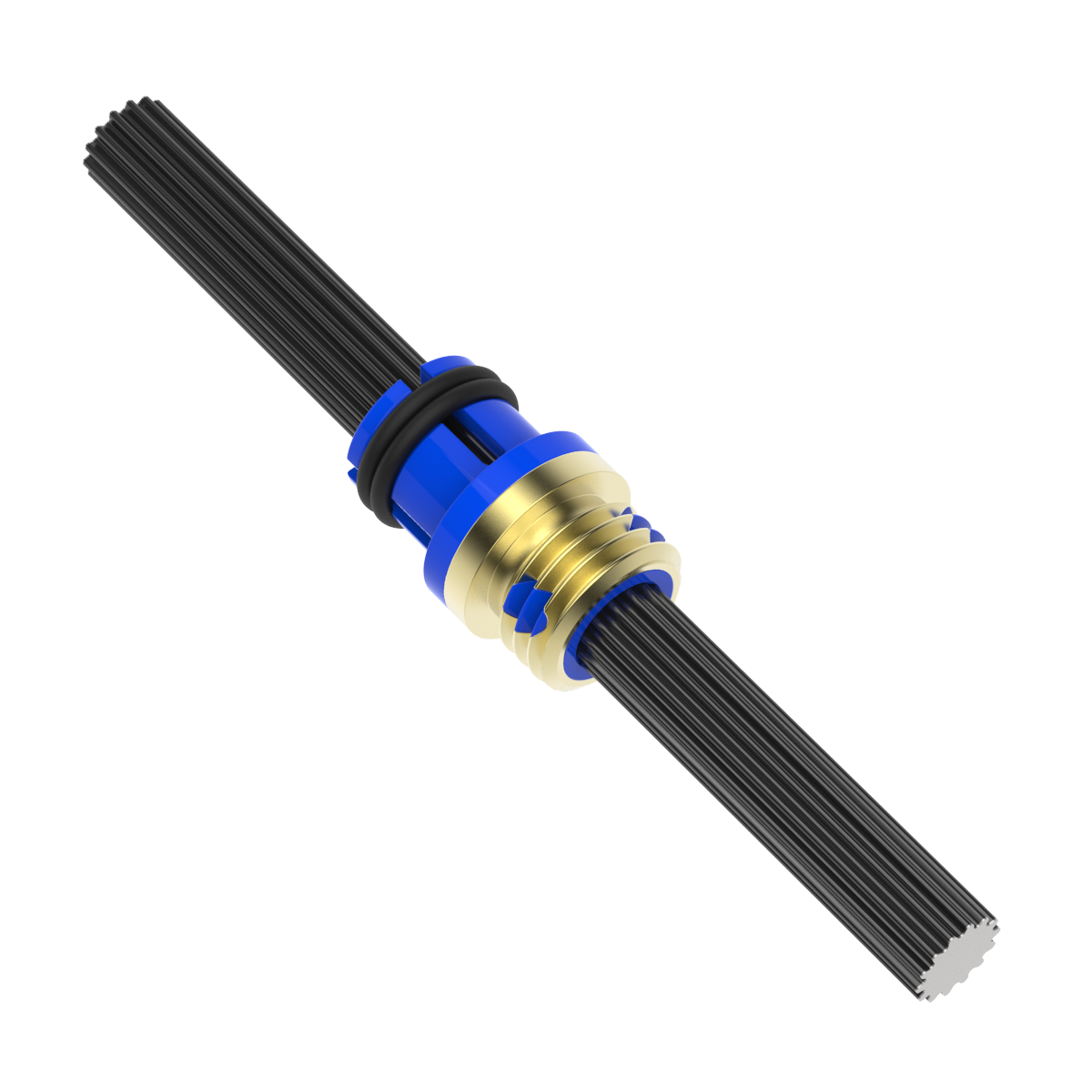

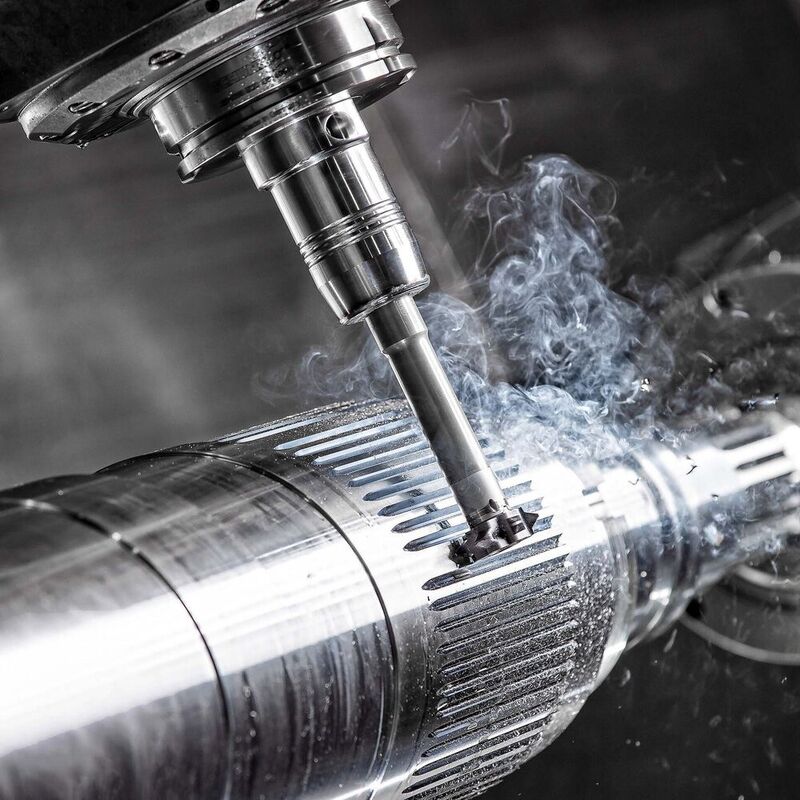

(Bild: Horn/ Sauermann) Tooling manufacturer Horn highlights one of its customers that is saving costs by not only turning a drive shaft on a multi-tasking CNC lathe but also milling a spline in the same set-up, an operation that was previously subcontracted out.

SAVE - Enco

Ingersoll's NuMaxHF high-feed, steep-ramping inserts offered in two styles

Milling machine gear box spline shaft. Gear shaft A60 Shift pinion shaft Gear Bull.

Bridgeport Milling Machine Part Gear Spline Shaft Gear Shift Pinion Shaft Fit 1p

Gear cutting tools, Liebherr

CECO-USA 20 Function Bike Tool with Chain Breaker – Bicycle Multi Tool – Heavy Duty, Compact Pocket Sized, Lightweight – High Strength CR-V 6150 Tool Steel – Easy To Carry : Sports & Outdoors

CNC Machining The Federal Group USA

Horn Expands Cartridge Tooling System For Grooving And Parting-Off - MTDCNC

Gear Cutting Tools

How to Keep Costs Down with Low Volume Production Machining - Schantz Machine & Fabrication

:quality(80)/p7i.vogel.de/wcms/68/94/6894d73dcd151a77d56c6a64eea88fc6/0115976371.jpeg)

In-cycle spline milling saves production costs

:quality(80)/p7i.vogel.de/wcms/e7/55/e755d72d3bdce3072f2cd57d384394e1/0112611632.jpeg?v=)

Horn Cutting Tools Ltd

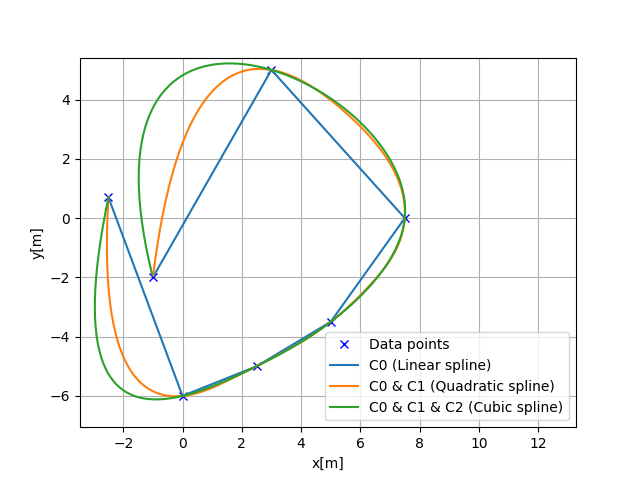

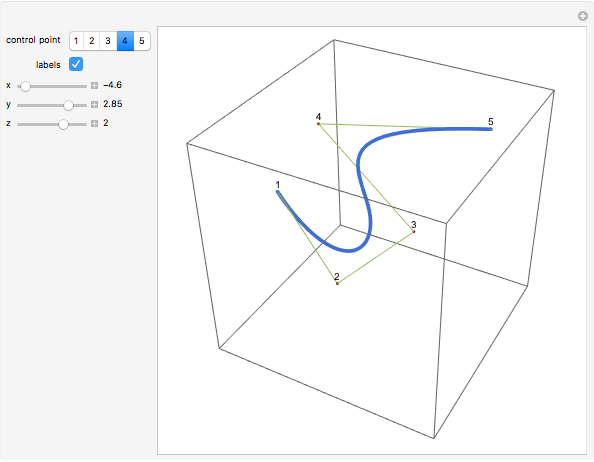

Sensors, Free Full-Text

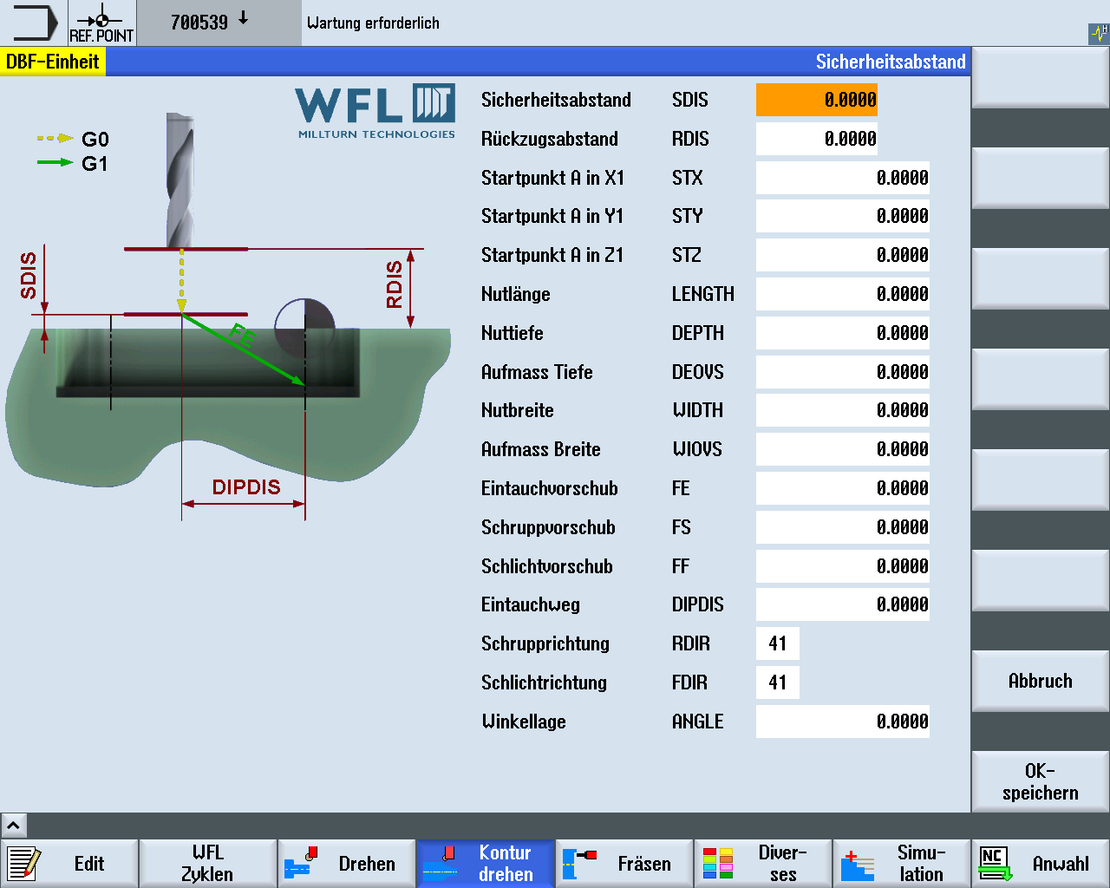

WFL Cycles - WFL

CNC Machining The Federal Group USA