Which Casting Process Should I Use? - Batesville products, inc.

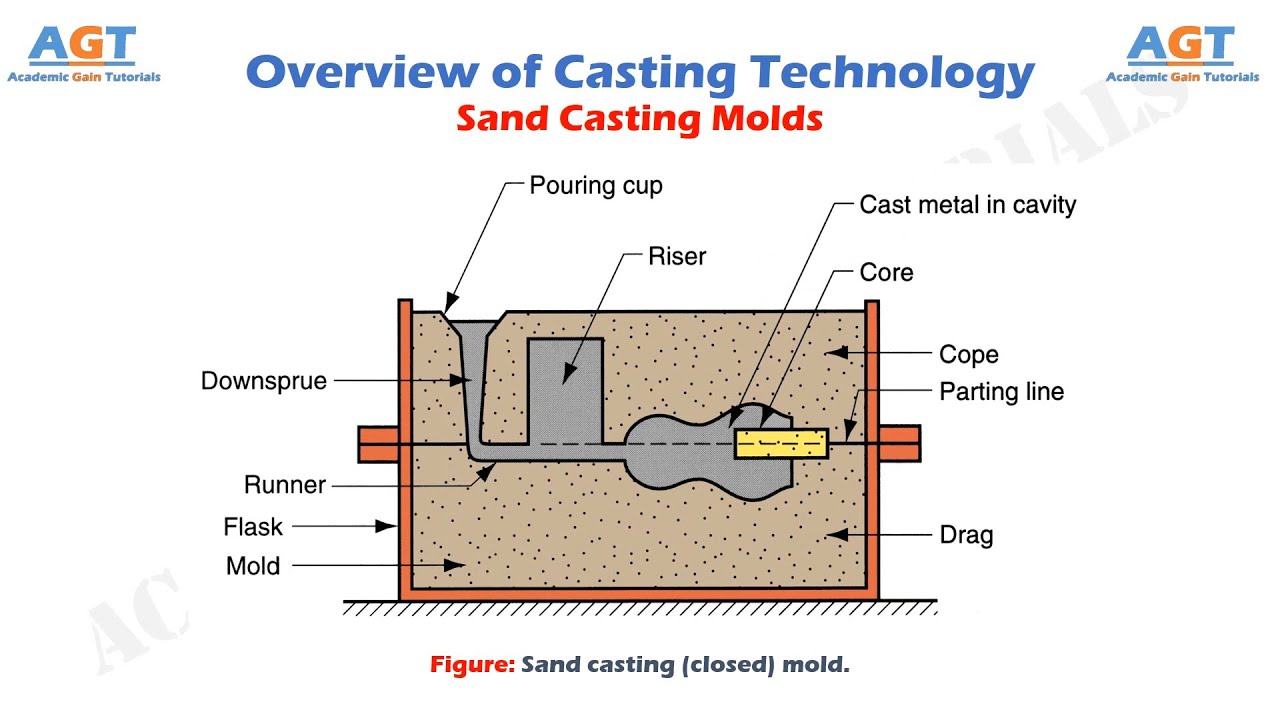

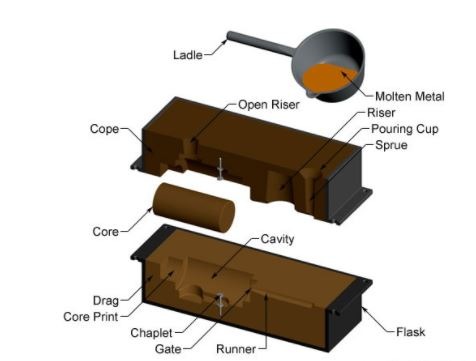

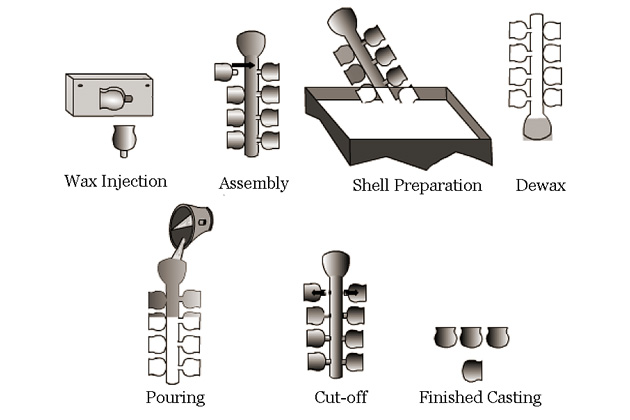

Pros and Cons of 5 Casting Processes: Sand, Permanent Mold, Die, Investment, and Lost Foam With so many casting processes, it can be hard to decide which one to use. Therefore, it is important to understand each option and how it relates to production costs, production volume, casting size, tolerance, surface finish, complexity and more.

Our resources - Batesville products, inc.

Sand Casting vs. Permanent Mold - Batesville products, inc.

Which Casting Process Should I Use? - Batesville products, inc.

PODCAST: Engineer's Guide to Metalcasting Processes

Rachel Weber on LinkedIn: PODCAST: Casting Simulation Technology - Batesville products, inc.

Who is Batesville Aluminum Castings?, Being the experts in aluminum and zinc castings, we can help you with ANY aluminum casting. Die Casting, Sand Casting, Investment Casting, Permenent Mold

Batesville Products Offers - Batesville products, inc.

Batesville Products, Inc.

Manufacturing Day American Foundry Society

Batesville Products Inc.

Len Weber - President and COO - Batesville Products, Inc.

6 Different Types of Casting process common used in Metal Foundries

Aluminum castings for architectural uses, Batesville Products, Inc - BPI

Videos Archives - Batesville products, inc.