Cutting, Blanking, Shearing & Trimming - AHSS Guidelines

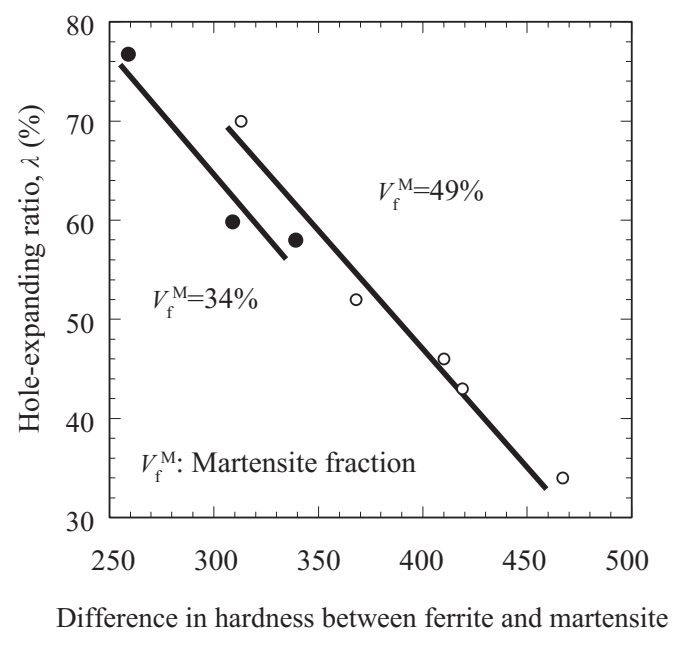

Advanced High-Strength Steels (AHSS) exhibit high degrees of work hardening, resulting in improved forming capabilities compared to conventional HSLA steels. However, the same high work hardening creates higher strength and hardness in sheared or punched edges, leading to reduced edge ductility. Microstructural features in some AHSS grades contribute to their sheared edge performance.

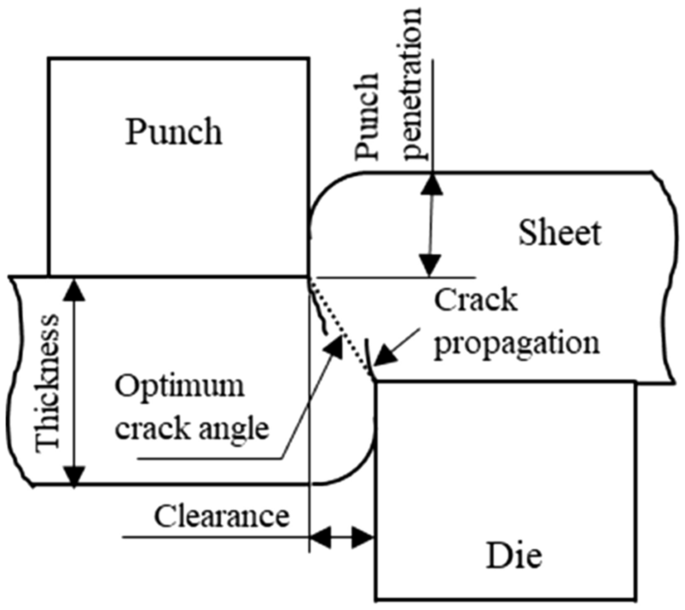

Sheet Metal Shearing Process: An Overview Transactions of the Indian National Academy of Engineering

Press Requirements - AHSS Guidelines

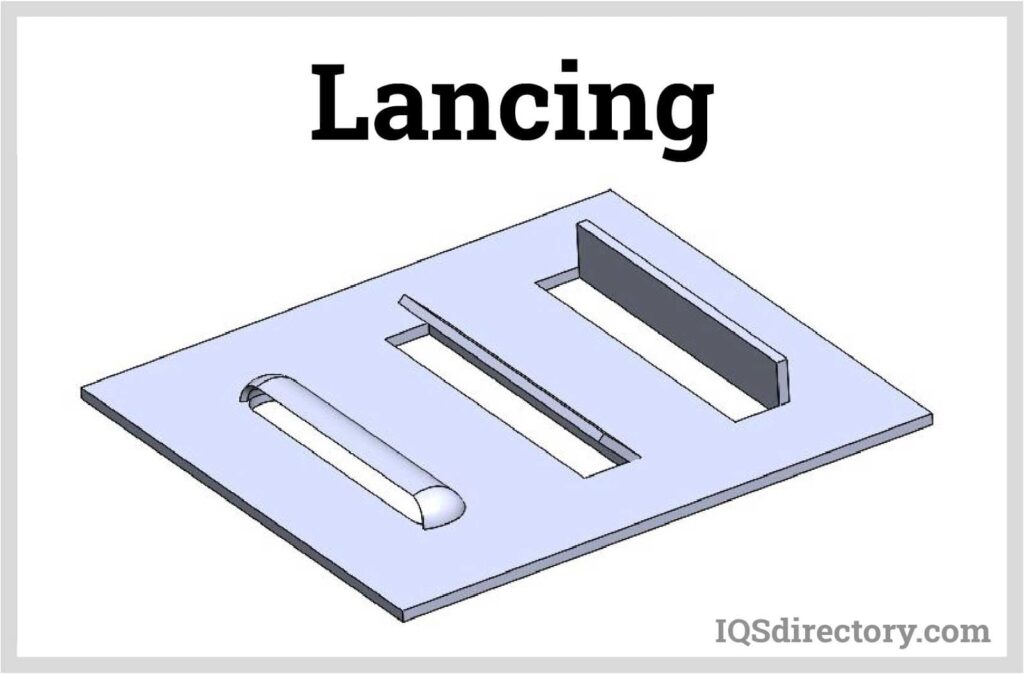

Different Types of Trimming Operations in Sheet Metal Manufacturing - CNC Machining Service, Rapid prototyping

Investigations on the flanging characteristics of advanced high-strength sheet metals with different sheared edge quality

Stretch flanging and hole expansion with AHSS

Cutting-Blanking-Shearing-Trimming Archives - AHSS Guidelines

final SALE】shear long best - ワンピース

PDF] Experimental Examination of Effects of Punch Angle and Clearance on Shearing Force and Estimation of Shearing Force Using Fuzzy Logic

Numerical prediction of sheared edge profiles in sheet metal trimming using ductile fracture modeling - ScienceDirect

Effect of Inclined Angle in Trimming of Ultra-high Strength Steel Sheets Having Inclined and Curved

Forming Limit Curves (FLC) - AHSS Guidelines

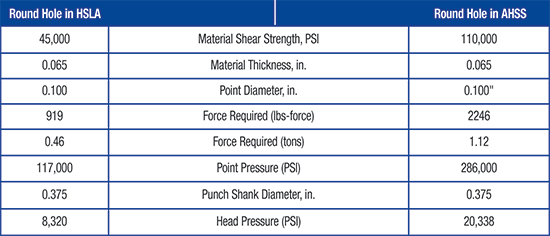

Cutting and Punching Advanced High-Strength Steels

Reducing the shear affected zone to improve the edge formability using a two-stage shear cutting simulation - ScienceDirect

Improvement by Metallurgical Approaches - AHSS Guidelines

Stretch flanging and hole expansion with AHSS