Sheet Metal Hemming, Hem Types & Processes Explained

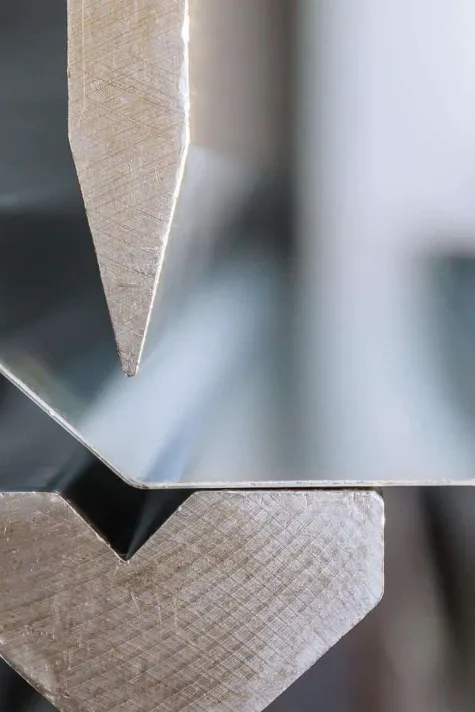

Hemming is a sheet metal forming process where the edge is folded onto itself. Hems make a part more durable and improve its appearance.

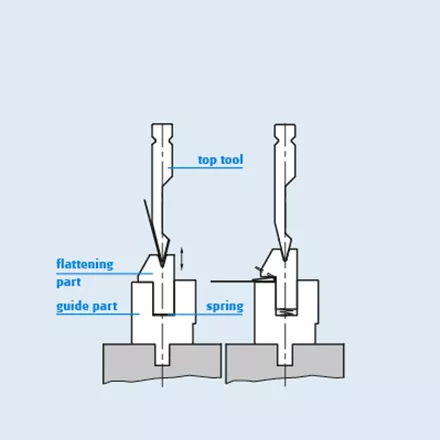

Die hemming carried out in 2 steps, manual flattening on a press brake

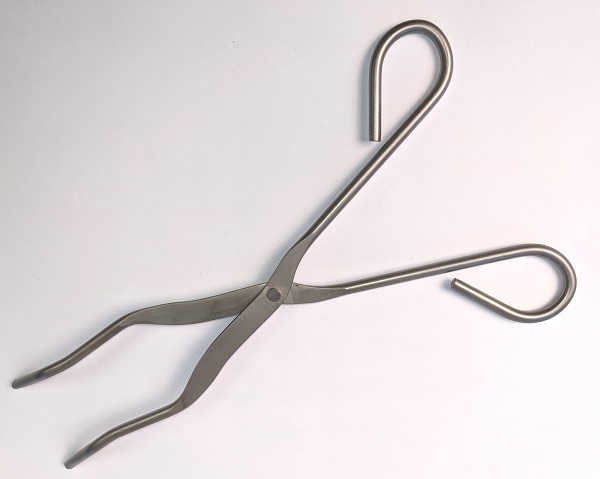

Hem roll die set, 3 rollers

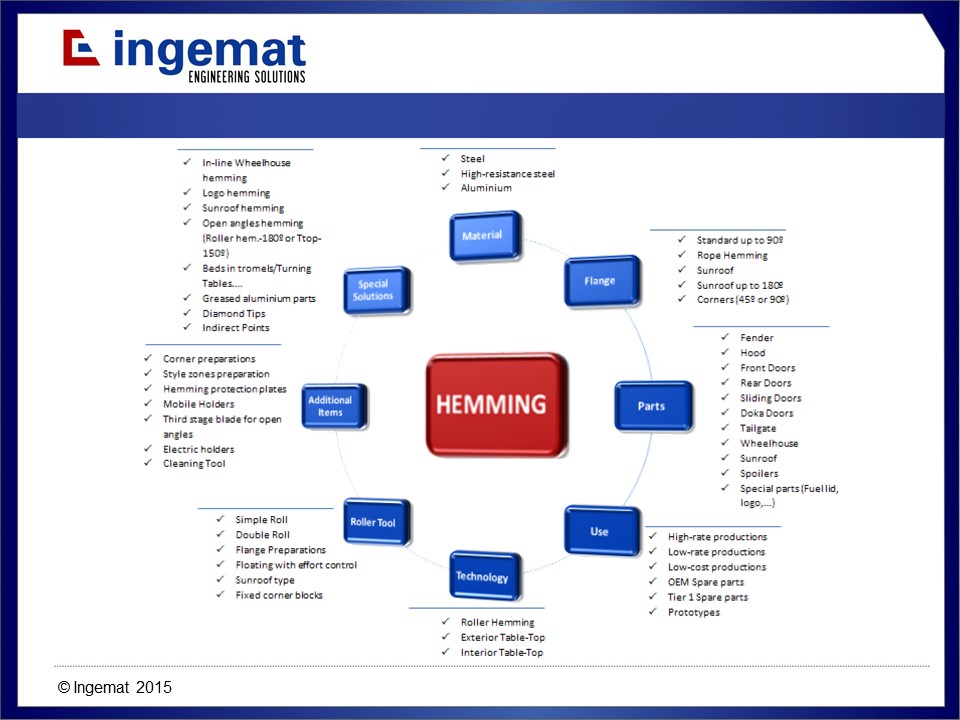

Roller Hemming offers high flexibility, automotive parts.

Sheet Metal Hemming, Hem Types & Processes Explained

Solved] “Hems and seams” are related to

Three-step hemming process and associated terminologies

What are the right advice during the hemming challenges

Sheet Metal, What is it and how does it work?

Sheet Metal Hemming, Hem Types & Processes Explained

Sheet Metal Hemming Explained and Its Types - WayKen

Hemming and seaming - Wikipedia

7 Ways to Improve Sheet Metal Parts

Hemming Technology

Hem Roll Set - Steel (3 Bead Roll Sets)

Sheet Metal Hem: The Complete Guide

Sheet Metal Box : 12 Steps (with Pictures) - Instructables